Real-time analytics plays a crucial role in facilitating predictive maintenance for companies, enabling them to proactively address equipment issues, reduce downtime, and optimize maintenance schedules. Here's how real-time analytics can contribute to effective predictive maintenance:

Continuous Monitoring

Real-time analytics allows companies to continuously monitor the performance of machinery and equipment. Sensors and IoT devices can provide real-time data on variables such as temperature, vibration, and other operational parameters. By analyzing this data in real time, companies can detect anomalies and early signs of potential equipment failures.

Anomaly Detection

Real-time analytics helps identify abnormal patterns or deviations from normal operating conditions. By establishing baseline performance metrics, any unusual behavior or unexpected changes in equipment parameters can be quickly detected. This proactive approach enables companies to intervene before a failure occurs, minimizing downtime and preventing costly repairs.

Condition-Based Monitoring

Real-time analytics enables condition-based monitoring, where the health and performance of equipment are assessed in real time. By integrating data from various sensors, companies can gain a holistic view of equipment conditions. This data-driven approach allows for targeted maintenance interventions based on the actual condition of the equipment, rather than fixed, scheduled maintenance routines.

Predictive Modeling

Real-time analytics facilitates the creation and deployment of predictive models. Machine learning algorithms can analyze historical and real-time data to predict when equipment is likely to fail. These predictive models become more accurate over time as they continuously learn from new data, enabling companies to schedule maintenance activities precisely when needed.

Prescriptive Analytics

In addition to predicting potential failures, real-time analytics can provide prescriptive insights on the actions to be taken. Based on the predictive models and real-time data, companies can receive recommendations on the most effective maintenance actions, whether it's scheduling preventive maintenance, replacing specific components, or optimizing operating parameters.

Reduced Downtime and Costs

Real-time analytics in predictive maintenance helps companies reduce unplanned downtime. By addressing issues before they escalate, companies can schedule maintenance during planned downtime, avoiding disruptions to regular operations. This not only minimizes the impact on production but also reduces overall maintenance costs.

Asset Lifecycle Management

Real-time analytics supports comprehensive asset lifecycle management. By continuously monitoring equipment performance and predicting maintenance needs, companies can extend the lifespan of their assets. This strategic approach ensures that assets are maintained optimally, maximizing their efficiency and return on investment.

Integration with Enterprise Systems

Real-time analytics can be seamlessly integrated with enterprise resource planning (ERP) systems, maintenance management systems, and other relevant platforms. This integration ensures a holistic view of operations, enabling better decision-making regarding maintenance activities and resource allocation.

In summary, real-time analytics empowers companies to shift from reactive to proactive maintenance strategies by continuously monitoring equipment, detecting anomalies, and leveraging predictive models. This results in increased operational efficiency, reduced downtime, and optimized maintenance costs, ultimately contributing to improved overall asset performance and longevity.

Technical Foundations

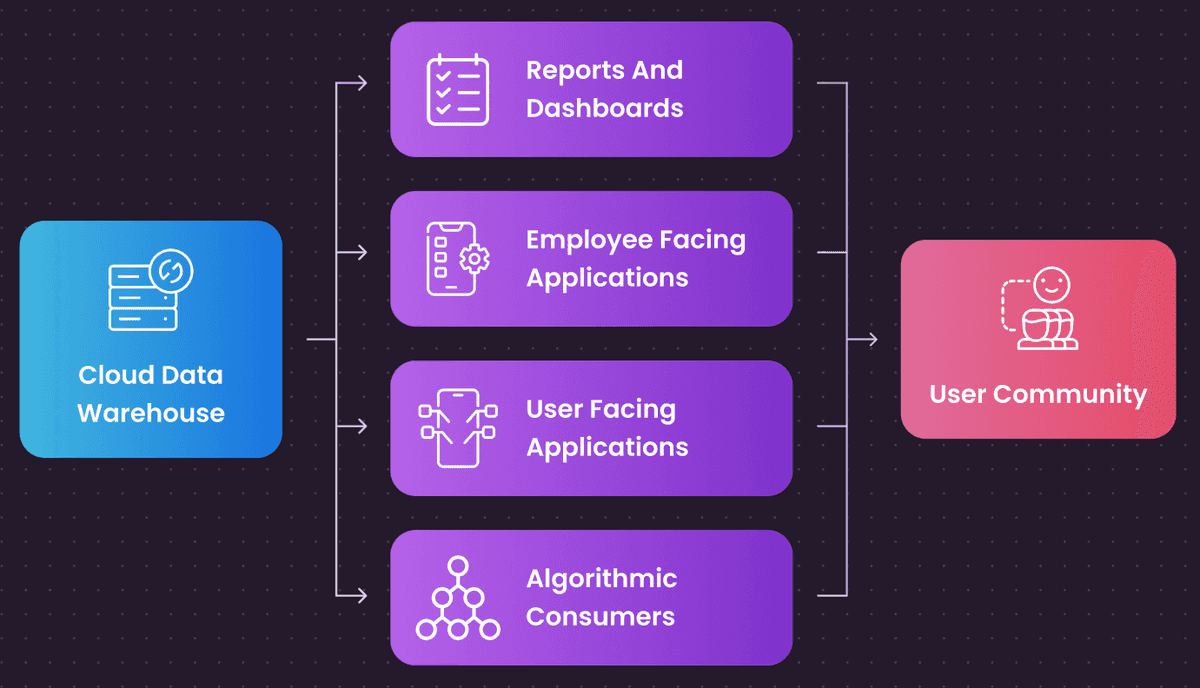

Unfortunately, traditional tools and approaches to data and analytics do not scale to deliver solutions like this.

There are too many delays in the process, and the systems often used are not performant enough to process high volumes of data with low latency. In addition, traditional business intelligence tools are not rich and flexible enough to meet the business demands.

This technology stack needs to be re-invented for the cloud, with tools and architectural patterns that are built for real-time advanced use cases and predictive analytics:

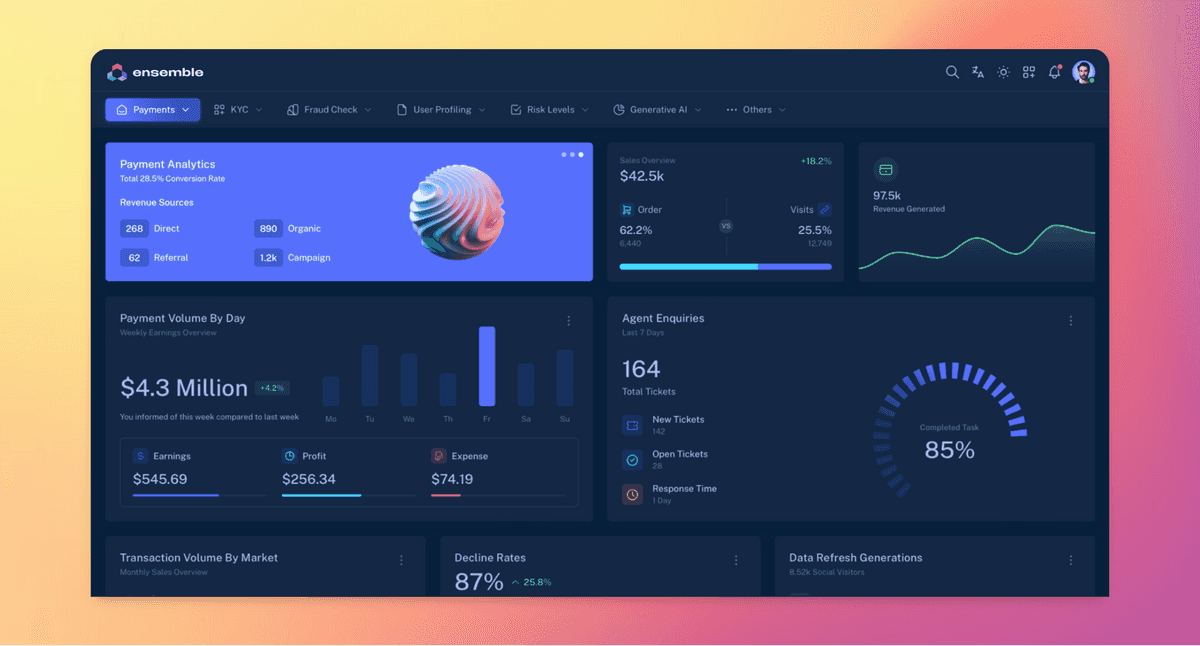

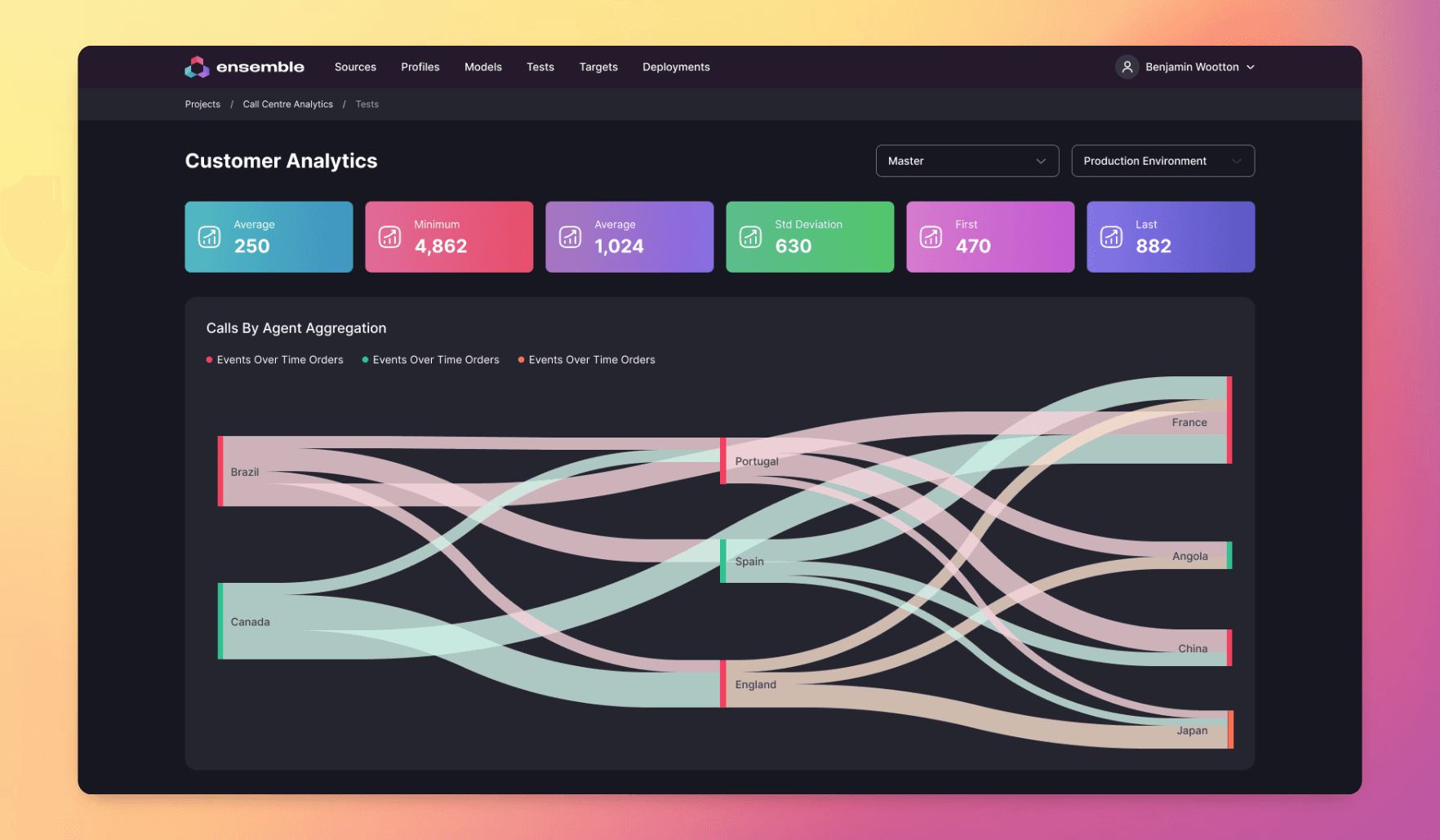

Introducing Ensemble

We are Ensemble, and we help enterprise organisations build and run sophisticated data, analytics and AI systems that drive growth, increase efficiency, enhance their customer experience and reduce risks.

We have a particular focus on ClickHouse, the fastest open-source database in the market, which we believe is the fastest best data platform for systems like this.

Want to learn more? Visit our home page or download our free report that describes the process for implementing advanced analytics in your business.